FREITAG上海現所旗艦店 FREITAG Store Shanghaihai FREITAG上海现所旗舰店

- 敷地 site 场地

-

中国上海

Shanghai,China

中国上海

- 主要用途 program 主要功能

-

店舗

Store

店铺

- 建築面積 site area 用地面积

-

95.5㎡

95.5㎡

95.5㎡

- 延面積 floor area 总建筑面积

-

263.5㎡

263.5㎡

263.5㎡

- 施主 client 业主

-

FREITAG

FREITAG

FREITAG

- 設計 design 设计

-

株式会社小大建築設計事務所

kooo architects

小大建筑设计事务所

- 担当 staff 负责人

-

小嶋伸也・小嶋綾香・何未聞・北上紘太郎・候雨彤・小川恭平

SHINYA KOJIMA・ AYAKA KOJIMA・Weiwen He・KOTARO KITAKAMI・Yutong Hou・Kyohei Ogawa

小嶋伸也・小嶋綾香・何未聞・北上紘太郎・候雨彤・小川恭平

- 施工 construction 施工

-

上海恒品装飾設計工程有限公司

HengPin

上海恒品装饰设计工程有限公司

- 写真 photo 摄影

-

堀越圭晋/ エスエス

HORIKOSHI KEISHIN/SS

堀越圭晋/SS

- FREITAG ベンチデザイン FREITAG Bench Design

-

Leandro Destefani (Zauber Aller Art), Zürich

Leandro Destefani (Zauber Aller Art), ZURICH

- ルーフトップ・コンセプト Concept Rooftop

-

Jody Wong, Zürich

Jody Wong, ZURICH

FREITAG Store Shanghai(フライターグ上海)は上海の中心地である静安寺エリアの北側に位置し、レジデンシャルエリアに位置ながらも近年は小さなカフェや商業施設などで盛り上がりを見せるエリアに位置する、チューリッヒ店に次ぐ大規模店舗である。

今プロジェクトで、私たちはブランドのストーリーを計画地、周辺環境と共に紡ぎ、循環型のストアコンセプトを打ち出したいと考えた。 そこで、計画地にあった既存の建築(1970~80年代に建設された国営のタオル工場)を出来る限り活用しながら、ストラクチャー部分を強化することで、より長寿命な建築物に移行させることにした。

ショップは延平路(Yan Ping Lu)と胶州路(Jiao Zhou Lu)を繋ぐ小さな路地(計画地の前面道路幅が約3mと狭く、そもそも再建築が困難な高密度住宅地域)にあり、二つの通りからもその姿を眺められるような場所に位置する。

長くても2、3年で通りのショップが移り変わる中国のトレンド、商業の考え方において。テナントと長期契約を結んだFREITAGからは「Waste is a design error 無駄はデザインのエラーである」という、環境に対しての信念のある厳格な設計依頼をもらった。

CO2の排出量を最大限抑えるという、表層だけのサステナブルデザインではない、骨太なプロジェクトであった。

施工工程としては開口部が少ない閉じられたコンクリートとレンガで作られた既存建築に対して、小型の重機を現場に入れて鉄骨で部分的に構造補強を入れながら街に対して大きく開く。または自然光や自然通風を取り入れる開口を開けていく作業を少しづつ行なっていった。その施工過程の中で、例えば現場の工事の仮囲いはリースでレンタルをするのではなく、最終的に既存建築のファサードとの間に断熱材を入れて仕上げにもそのまま用いるデッキプレートを使ったり(資材運搬による環境汚染の減少)。解体した端材の廃材に現場でモルタルを混ぜて、再生ブロック(資源循環)を作り、新しい1階の床材にそのまま転用するなど。思いつく限りのありとあらゆる無駄やロスが出ないデザイン手法を導入した。

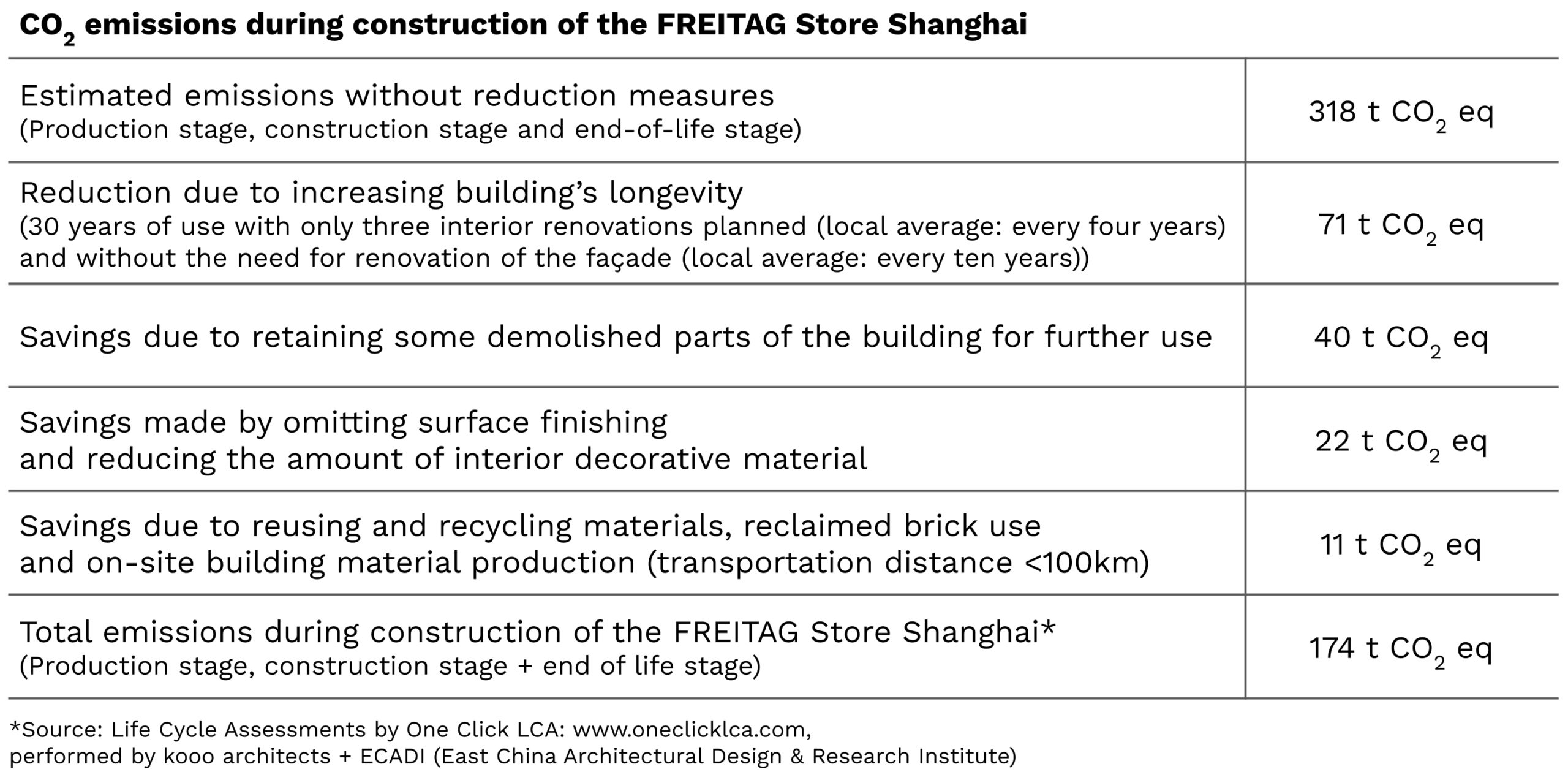

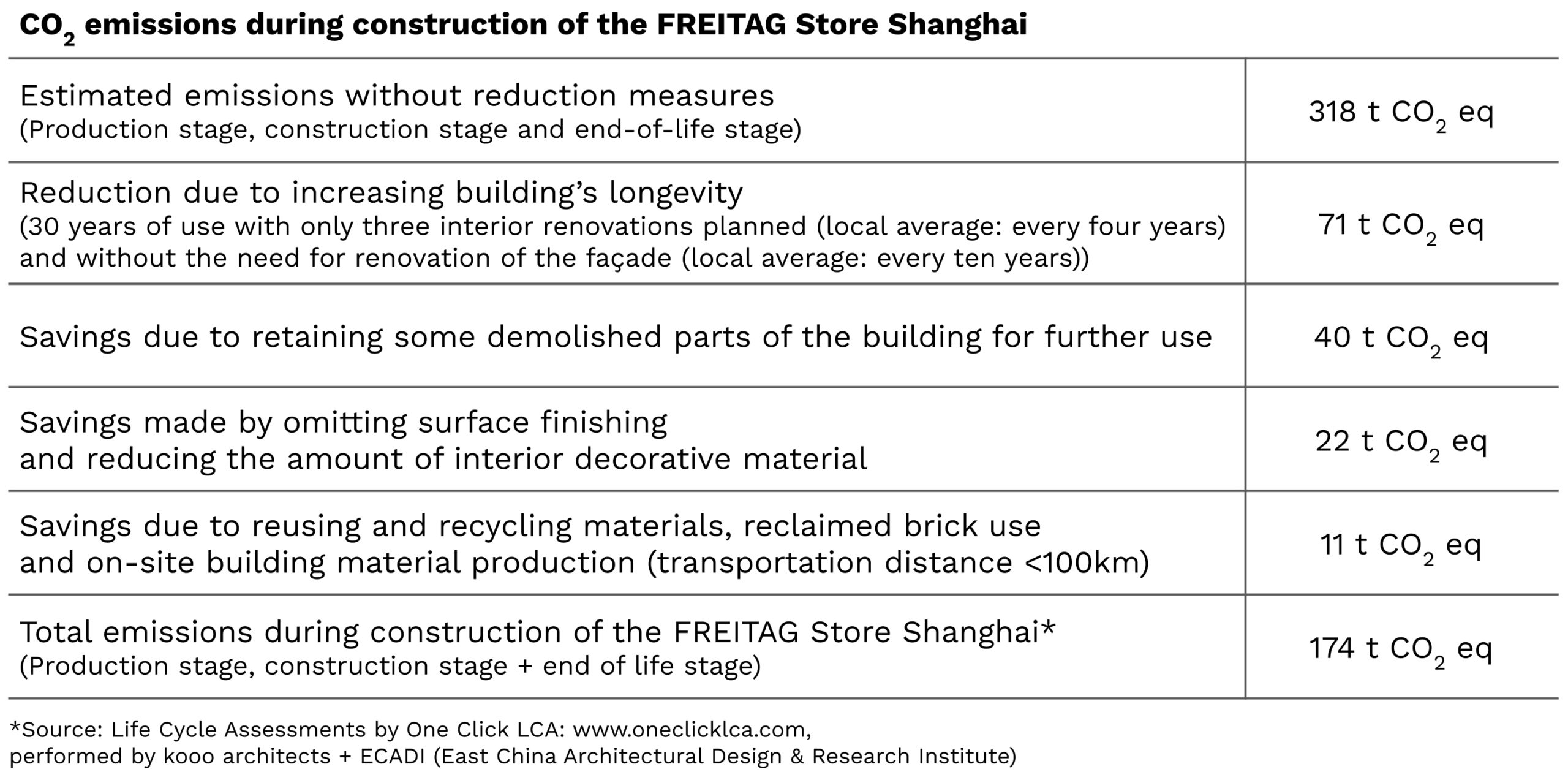

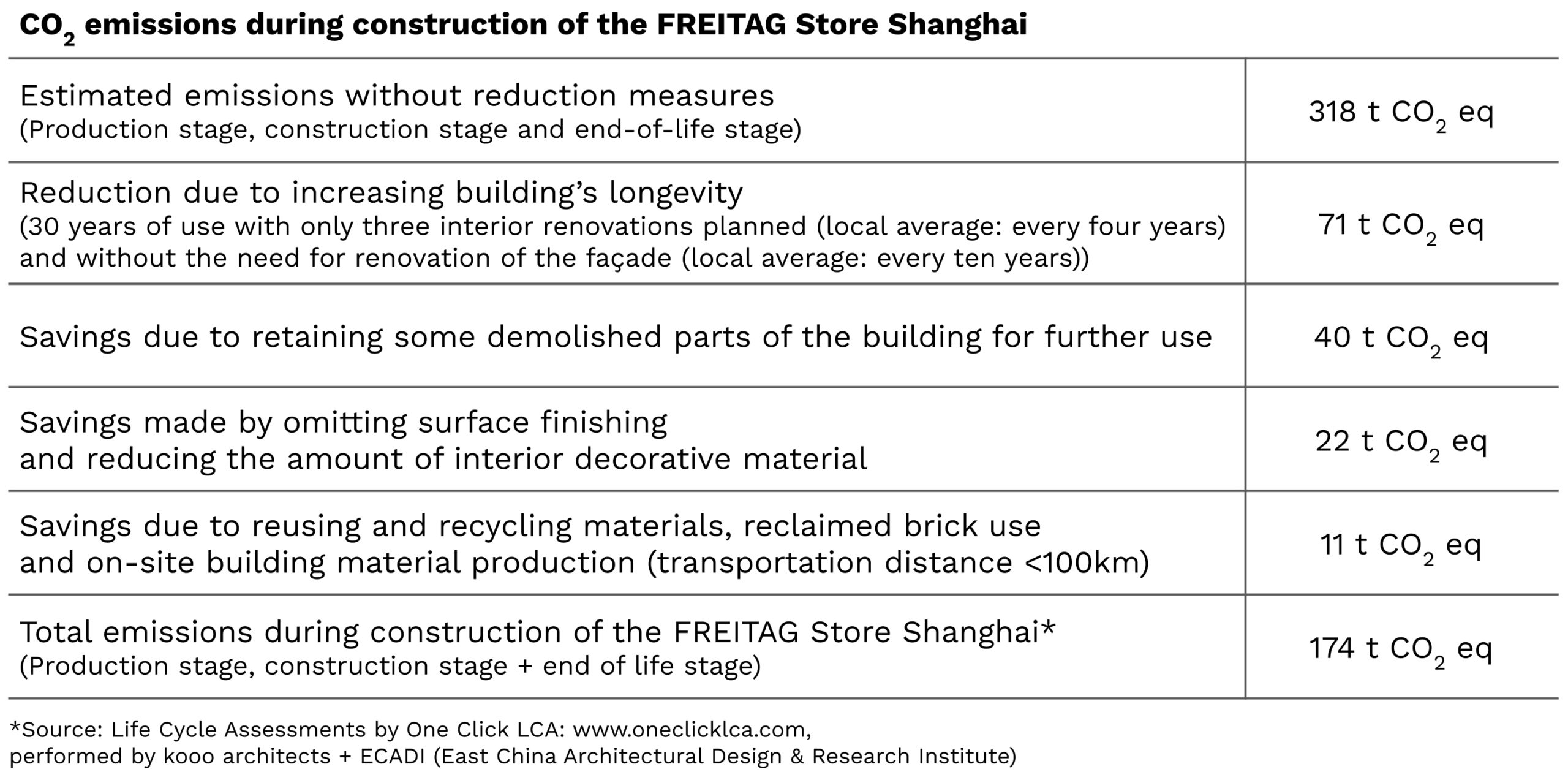

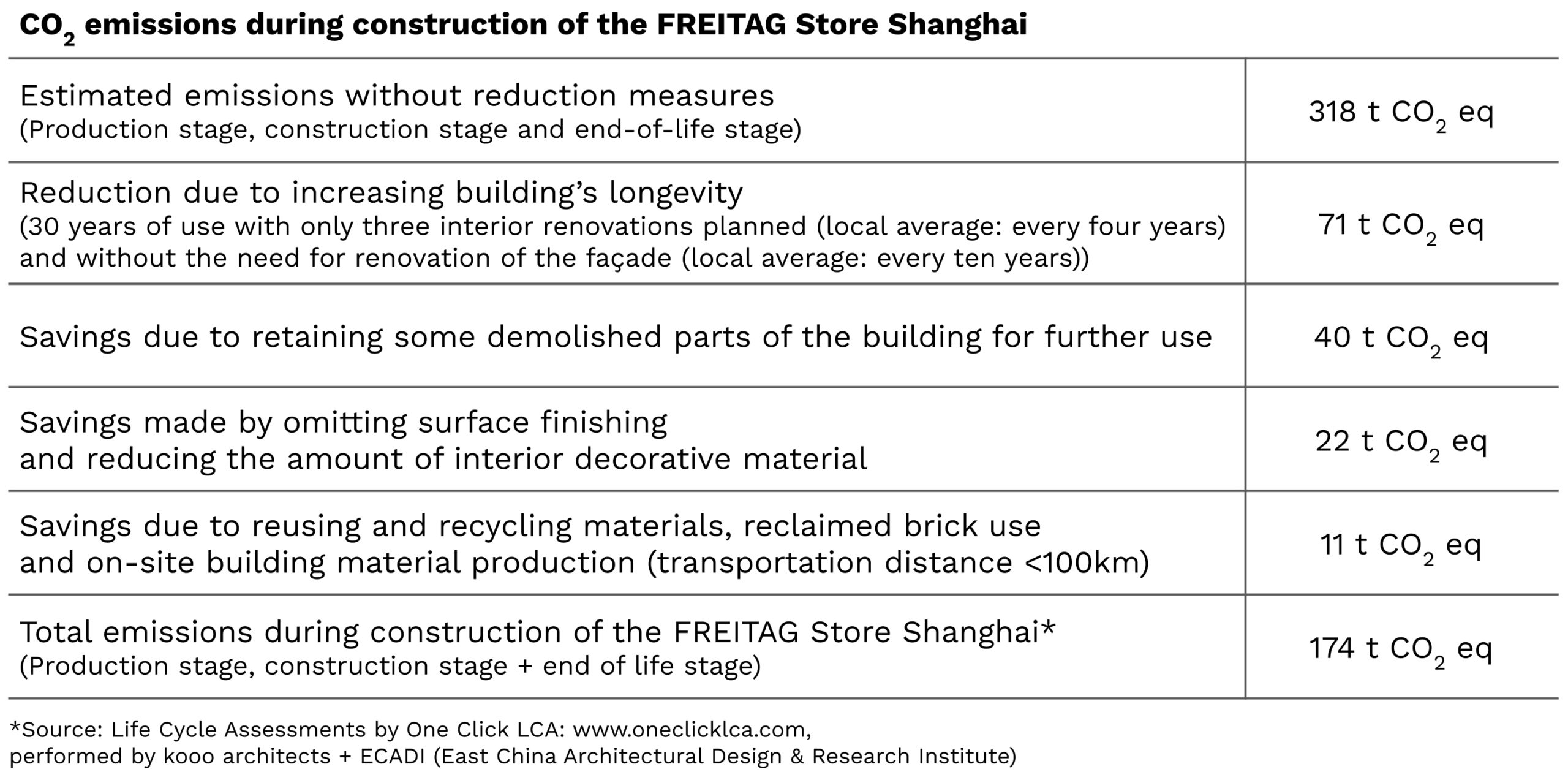

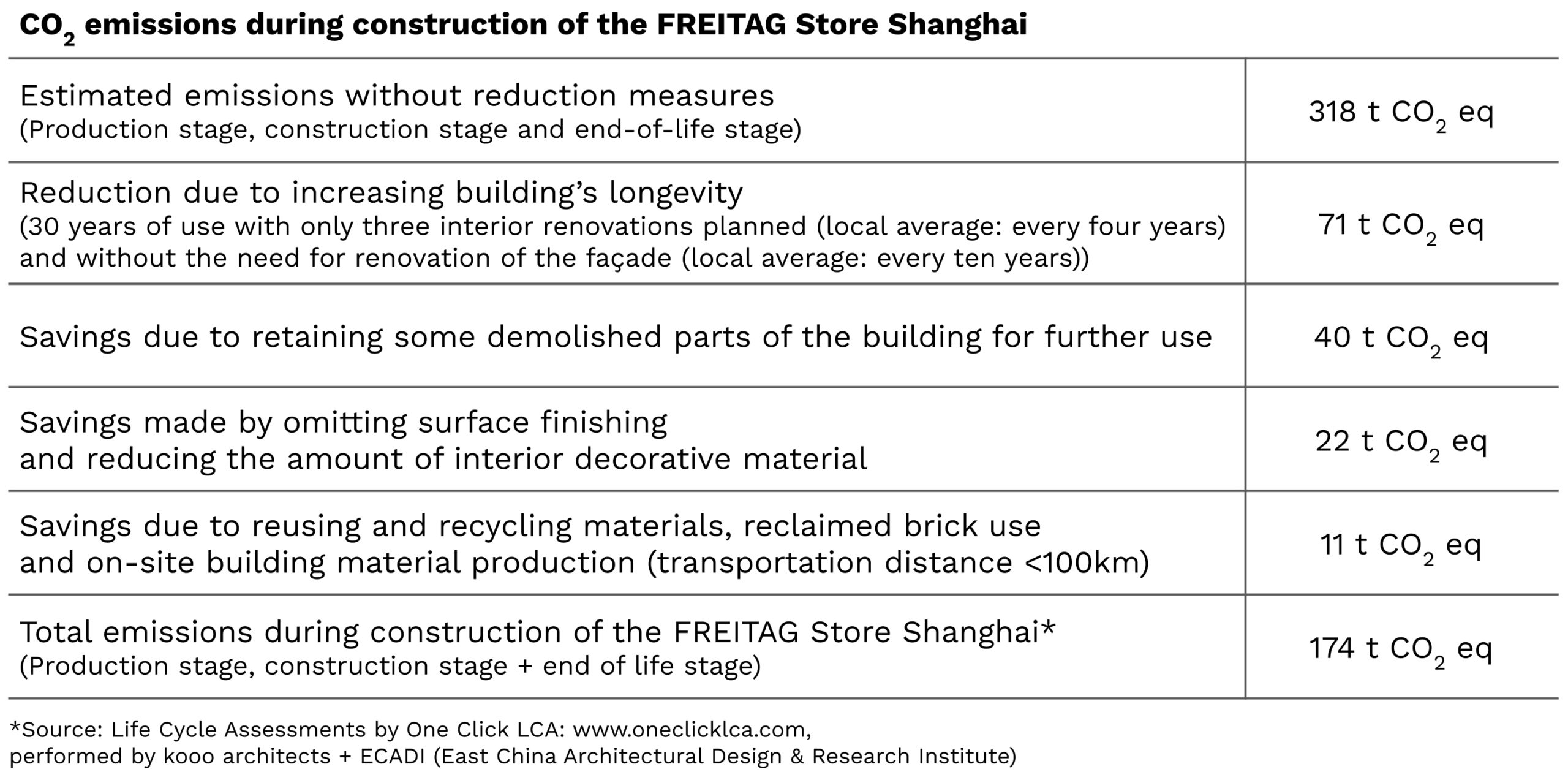

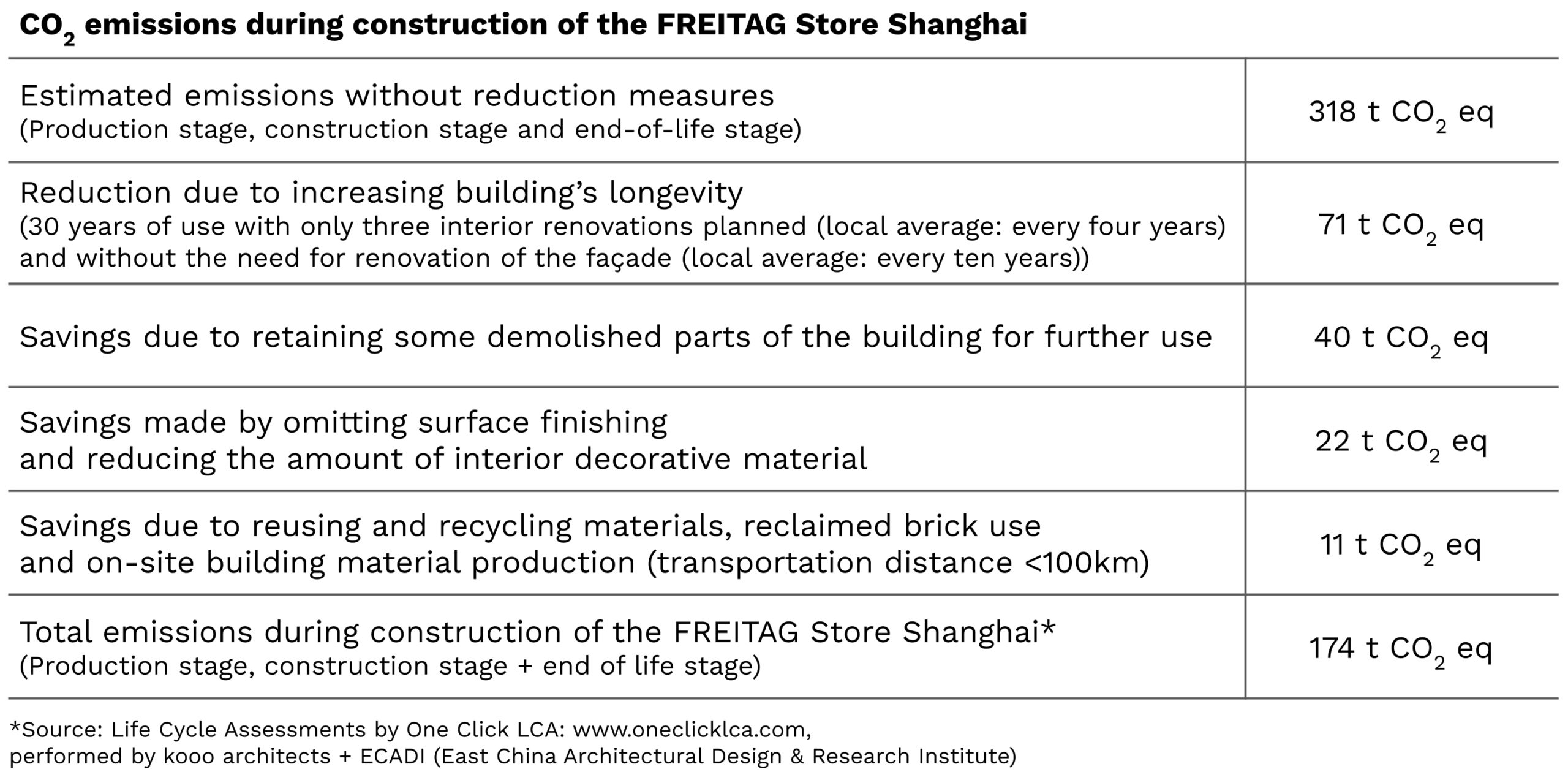

また、上海FREITAG新店舗の改装では、CO2排出量を最小限に抑えることに重点を置き、さまざまな対策により、約144t-CO2 eq(約45%)の削減を達成することができた。この数字は、生産、建設、使用後の段階を含み、11,500本のブナの木が1年間に吸収するCO2の量に相当するもの。また、205,000kWhの電力(East China Power Grid)や48.2トンのガソリンを使用した場合にも、同量のCO2が排出されることになる。

この小さな路地に計画された店舗がコミュニティに開かれた存在となることを目指し、1階はリペアステーションが計画された。また各階をつなぐ大きなヴォイドに沿うように店内に垂直収納システムを採用。裏方的な機能を、室内空間全体の中心的な機能としてみせている。垂直収納は各階に1つずつあり、ローテクな手動機構によって床板に向かって移動させることも可能である。 今店舗がコミュニティと共に長く愛される場所、そしてブランドを作るターミナルのような場所になることを願う。

FREITAG Store Shanghai is located in Xian-Suo district, north of Jing’an Temple in the heart of Shanghai, an area that has recently seen a rise in small cafes and commercial facilities, despite being residential.

Found on a small alley connecting Yan Pinglu and Jiaozhou Lu, it is designed to be visible from both streets.

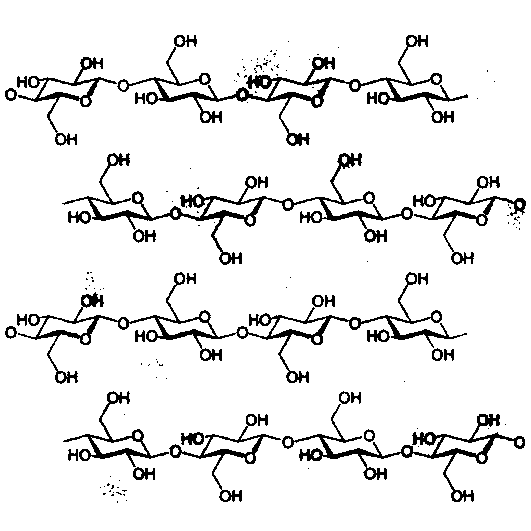

FREITAG is a bag brand born in 1993 in an industrial area of Zurich, Switzerland. The founders, the Freitag brothers, took inspiration from colorful trucks when they designed the first Freitag bag (now a very well-known story), which consisted entirely of recycled materials, used truck tarpaulins, discarded bicycle tubes, and car seat belts.

As FREITAG reuses discarded materials not only for its bags but also in its store design, with this project, we wanted to weave the brand story with the site and surrounding environment to create a concept with the saving of resources at its core.

Therefore, we decided to recycle as much of the existing architecture on the proposed site (a state-run textile factory built in the 1970s-1980s) while strengthening the structural parts to transition it into a longer-lasting building. Minimization of CO2 emissions was a key requirement. The entire building process was geared to this end, and the footprint of the conversion analyzed in detail.

Elements retrieved from the existing building were retained or reused wherever possible. And when there was no way to avoid the use of new materials, they were sourced within a radius of around 100 kilometers. The old walls were demolished with the utmost care to facilitate the reuse of as many intact bricks as possible. Rubble from the demolition of ceilings and walls was collected to make so-called “rebirth bricks” on site that could be used for the new floors, and the hoarding panels that had enveloped the entire building during reconstruction work and protected passers-by and the neighborhood from debris and dust was cut and repurposed on-site into a characteristic facade. The steel structural frame refinedly touches the ground, effectively widening the alley and providing space for external activities and circulation.

Construct the façade with deck plate re-used from the hoarding. It was determined in the planning stage of construction, when we knew a fully enclosed hoarding made with metal was necessary to provide undisturbed construction environment for this project. We saw the material similarity between the hoarding and our designed deck plate façade, so we decided to use the deck plate as the hoarding material. In later stages of construction, the deck plate was removed from hoarding, trimmed to size and reinstalled as permanent façade material. Eventually, about 65% of the façade was directly adapted from the hoarding and through which we avoided using single-use metal panels for the hoarding to a degree.

The new facade’s slightly larger window sections give an insight into the building’s history.

After the 2008 Sichuan earthquake, it was the first time when building debris was used to mass-produce bricks as post-catastrophic rebuilding material, and thus it was named rebirth brick. Inspired by the act, we are site-producing cement-based bricks by adding architectural waste into the brick mold. As a result, we produce the brick material with a handcrafted look that also consumes some waste from demolition in the process. Rebirth brick would be used mainly as 1F floor paving material. From the paving, debris of red brick, white ceramic or black terrazzo are still visible. We find it particularly meaningful to craft unique-looking material that contains part of the old building and serves as the basis/ground of the new.

The second and third floors are accessed from the outside via an exterior staircase painted in “Traffic Yellow,” one of the brand’s image colors.

この外階段だけでなく、カーゴリフト、ハシゴなど、垂直方向の移動に関連する要素には「Traffic Yellow」を採用することで、主にモノトーン(今回は彼らがよく使用する「Industry Grey」もインテリアエレメンツに多く採用した)となっている建築、インテリア要素に視認性と、ワクワク感をもたらしている。

The use of “Traffic Yellow” for this staircase as well as for elements related to vertical movements, such as cargo lifts and ladders, brings visibility and a sense of excitement to the architecture and interior, which is mainly monotone (painted in “Light Grey” often used by Freitag).

A repair station was planned on the first floor to ensure that FREITAG’s products have an even longer service life, all in the spirit of the circular economy.

As a part of the community, FREITAG has tried to create a genuinely rewarding space. A landscaped roof terrace, for example, is open to the public, and people in the neighborhood help to inject it with life. FREITAG Store Shanghai is a hybrid concept occupying the space between neighborhood and retail. We hope the store, which will open on March 25th, will become a long-lasting place within the community and a hub for the brand’s growth.

https://media.freitag.ch/ja/media/stores/shanghai

Project approach reduces emissions by 144 t CO2 eq (See the link above for details.)

Throughout the entire conversion of the new Shanghai FREITAG Store, the focus was on minimizing CO2 emissions.

Thanks to the use of various measures, they were reduced by around 144 t CO2 eq (approx. 45%).

This figure includes the production, construction and end-of-life stages and corresponds to the amount of CO2 absorbed jointly by 11,500 beech trees in a year.

The same amount of CO2 is also emitted during the production of 205,000 kWh of electricity (East China Power Grid) or the use of 48.2 tonnes of gasoline.

FREITAG 上海店位于上海市中心静安寺区域的北侧。该地区虽然主要为住宅区,但近年来随着小型咖啡馆和商业设施的不断兴起,逐渐呈现出活力与人气。本项目是继苏黎世店之后的大规模门店。

在本次设计中,我们希望将品牌故事与基地及周边环境相结合,提出一个循环型的店铺概念。因此,我们尽可能地利用基地内原有建筑(建于20世纪70~80年代的国营毛巾工厂),并通过结构加固,使其转变为更具长寿命的建筑物。

シ店铺位于连接延平路与胶州路的一条狭窄小巷内(前面道路宽约3米,是高密度住宅区,再建十分困难),同时从两条街道均可望见其姿态。在中国,街道商铺通常2至3年就会更替,而FREITAG与业主签订了长期租约,并提出了严格的设计要求:“Waste is a design error(浪费是设计的错误)”。因此,本项目不仅仅是表面上的可持续设计,而是一个真正着眼于减少CO2排放的“硬核”项目。

施工过程中,原有建筑是由混凝土与砖砌成的封闭空间,开口较少。我们在现场引入小型机械,在部分区域用钢结构进行补强,同时逐步打开建筑立面,使之面向城市敞开,并引入自然采光与自然通风。例如,工地的围挡不再租赁,而是直接采用钢筋压型板,后续在既有立面与新加保温层之间作为饰面继续使用(减少因运输材料带来的环境负担);又如,将拆除的废料与水泥砂浆混合,在现场制成再生砖块,并直接作为一层地面的铺装材料。我们尽可能地在每个环节中避免浪费与资源流失。

在本次改造中,我们重点控制CO2排放量,最终实现了约144吨二氧化碳当量(约45%)的削减。这一数值涵盖了生产、施工和使用后的阶段,相当于11,500棵山毛榉在一年内所吸收的二氧化碳量;换算成能源,相当于华东电网约205,000千瓦时的电力消耗,或48.2吨汽油的燃烧所产生的CO2排放量。

本项目也希望让这家开设在小巷内的店铺成为对社区开放的存在:一层规划了维修工坊;同时沿着贯穿各层的大型中庭设置了垂直储存系统。不同于一般隐藏在后台的设施,这里将其作为店铺空间的中心展示。垂直储存装置在每一层均设有一个,可通过简单的手动机械系统将货物移送至相应楼层。我们希望新店能够成为一个与社区共存、被长久喜爱的场所,并成为承载和传播品牌的“终端”。

READ MORE SHOW LESS

- 敷地 site 场地

-

中国上海

Shanghai,China

中国上海

- 主要用途 program 主要功能

-

店舗

Store

店铺

- 建築面積 site area 用地面积

-

95.5㎡

95.5㎡

95.5㎡

- 延面積 floor area 总建筑面积

-

263.5㎡

263.5㎡

263.5㎡

- 施主 client 业主

-

FREITAG

FREITAG

FREITAG

- 設計 design 设计

-

株式会社小大建築設計事務所

kooo architects

小大建筑设计事务所

- 担当 staff 负责人

-

小嶋伸也・小嶋綾香・何未聞・北上紘太郎・候雨彤・小川恭平

SHINYA KOJIMA・ AYAKA KOJIMA・Weiwen He・KOTARO KITAKAMI・Yutong Hou・Kyohei Ogawa

小嶋伸也・小嶋綾香・何未聞・北上紘太郎・候雨彤・小川恭平

- 施工 construction 施工

-

上海恒品装飾設計工程有限公司

HengPin

上海恒品装饰设计工程有限公司

- 写真 photo 摄影

-

堀越圭晋/ エスエス

HORIKOSHI KEISHIN/SS

堀越圭晋/SS

- FREITAG ベンチデザイン FREITAG Bench Design

-

Leandro Destefani (Zauber Aller Art), Zürich

Leandro Destefani (Zauber Aller Art), ZURICH

- ルーフトップ・コンセプト Concept Rooftop

-

Jody Wong, Zürich

Jody Wong, ZURICH

PROJECT DATA SHOW LESS

FREITAG Store Shanghai(フライターグ上海)は上海の中心地である静安寺エリアの北側に位置し、レジデンシャルエリアに位置ながらも近年は小さなカフェや商業施設などで盛り上がりを見せるエリアに位置する、チューリッヒ店に次ぐ大規模店舗である。

今プロジェクトで、私たちはブランドのストーリーを計画地、周辺環境と共に紡ぎ、循環型のストアコンセプトを打ち出したいと考えた。 そこで、計画地にあった既存の建築(1970~80年代に建設された国営のタオル工場)を出来る限り活用しながら、ストラクチャー部分を強化することで、より長寿命な建築物に移行させることにした。

ショップは延平路(Yan Ping Lu)と胶州路(Jiao Zhou Lu)を繋ぐ小さな路地(計画地の前面道路幅が約3mと狭く、そもそも再建築が困難な高密度住宅地域)にあり、二つの通りからもその姿を眺められるような場所に位置する。

長くても2、3年で通りのショップが移り変わる中国のトレンド、商業の考え方において。テナントと長期契約を結んだFREITAGからは「Waste is a design error 無駄はデザインのエラーである」という、環境に対しての信念のある厳格な設計依頼をもらった。

CO2の排出量を最大限抑えるという、表層だけのサステナブルデザインではない、骨太なプロジェクトであった。

施工工程としては開口部が少ない閉じられたコンクリートとレンガで作られた既存建築に対して、小型の重機を現場に入れて鉄骨で部分的に構造補強を入れながら街に対して大きく開く。または自然光や自然通風を取り入れる開口を開けていく作業を少しづつ行なっていった。その施工過程の中で、例えば現場の工事の仮囲いはリースでレンタルをするのではなく、最終的に既存建築のファサードとの間に断熱材を入れて仕上げにもそのまま用いるデッキプレートを使ったり(資材運搬による環境汚染の減少)。解体した端材の廃材に現場でモルタルを混ぜて、再生ブロック(資源循環)を作り、新しい1階の床材にそのまま転用するなど。思いつく限りのありとあらゆる無駄やロスが出ないデザイン手法を導入した。

また、上海FREITAG新店舗の改装では、CO2排出量を最小限に抑えることに重点を置き、さまざまな対策により、約144t-CO2 eq(約45%)の削減を達成することができた。この数字は、生産、建設、使用後の段階を含み、11,500本のブナの木が1年間に吸収するCO2の量に相当するもの。また、205,000kWhの電力(East China Power Grid)や48.2トンのガソリンを使用した場合にも、同量のCO2が排出されることになる。

この小さな路地に計画された店舗がコミュニティに開かれた存在となることを目指し、1階はリペアステーションが計画された。また各階をつなぐ大きなヴォイドに沿うように店内に垂直収納システムを採用。裏方的な機能を、室内空間全体の中心的な機能としてみせている。垂直収納は各階に1つずつあり、ローテクな手動機構によって床板に向かって移動させることも可能である。 今店舗がコミュニティと共に長く愛される場所、そしてブランドを作るターミナルのような場所になることを願う。

FREITAG Store Shanghai is located in Xian-Suo district, north of Jing’an Temple in the heart of Shanghai, an area that has recently seen a rise in small cafes and commercial facilities, despite being residential.

Found on a small alley connecting Yan Pinglu and Jiaozhou Lu, it is designed to be visible from both streets.

FREITAG is a bag brand born in 1993 in an industrial area of Zurich, Switzerland. The founders, the Freitag brothers, took inspiration from colorful trucks when they designed the first Freitag bag (now a very well-known story), which consisted entirely of recycled materials, used truck tarpaulins, discarded bicycle tubes, and car seat belts.

As FREITAG reuses discarded materials not only for its bags but also in its store design, with this project, we wanted to weave the brand story with the site and surrounding environment to create a concept with the saving of resources at its core.

Therefore, we decided to recycle as much of the existing architecture on the proposed site (a state-run textile factory built in the 1970s-1980s) while strengthening the structural parts to transition it into a longer-lasting building. Minimization of CO2 emissions was a key requirement. The entire building process was geared to this end, and the footprint of the conversion analyzed in detail.

Elements retrieved from the existing building were retained or reused wherever possible. And when there was no way to avoid the use of new materials, they were sourced within a radius of around 100 kilometers. The old walls were demolished with the utmost care to facilitate the reuse of as many intact bricks as possible. Rubble from the demolition of ceilings and walls was collected to make so-called “rebirth bricks” on site that could be used for the new floors, and the hoarding panels that had enveloped the entire building during reconstruction work and protected passers-by and the neighborhood from debris and dust was cut and repurposed on-site into a characteristic facade. The steel structural frame refinedly touches the ground, effectively widening the alley and providing space for external activities and circulation.

Construct the façade with deck plate re-used from the hoarding. It was determined in the planning stage of construction, when we knew a fully enclosed hoarding made with metal was necessary to provide undisturbed construction environment for this project. We saw the material similarity between the hoarding and our designed deck plate façade, so we decided to use the deck plate as the hoarding material. In later stages of construction, the deck plate was removed from hoarding, trimmed to size and reinstalled as permanent façade material. Eventually, about 65% of the façade was directly adapted from the hoarding and through which we avoided using single-use metal panels for the hoarding to a degree.

The new facade’s slightly larger window sections give an insight into the building’s history.

After the 2008 Sichuan earthquake, it was the first time when building debris was used to mass-produce bricks as post-catastrophic rebuilding material, and thus it was named rebirth brick. Inspired by the act, we are site-producing cement-based bricks by adding architectural waste into the brick mold. As a result, we produce the brick material with a handcrafted look that also consumes some waste from demolition in the process. Rebirth brick would be used mainly as 1F floor paving material. From the paving, debris of red brick, white ceramic or black terrazzo are still visible. We find it particularly meaningful to craft unique-looking material that contains part of the old building and serves as the basis/ground of the new.

The second and third floors are accessed from the outside via an exterior staircase painted in “Traffic Yellow,” one of the brand’s image colors.

この外階段だけでなく、カーゴリフト、ハシゴなど、垂直方向の移動に関連する要素には「Traffic Yellow」を採用することで、主にモノトーン(今回は彼らがよく使用する「Industry Grey」もインテリアエレメンツに多く採用した)となっている建築、インテリア要素に視認性と、ワクワク感をもたらしている。

The use of “Traffic Yellow” for this staircase as well as for elements related to vertical movements, such as cargo lifts and ladders, brings visibility and a sense of excitement to the architecture and interior, which is mainly monotone (painted in “Light Grey” often used by Freitag).

A repair station was planned on the first floor to ensure that FREITAG’s products have an even longer service life, all in the spirit of the circular economy.

As a part of the community, FREITAG has tried to create a genuinely rewarding space. A landscaped roof terrace, for example, is open to the public, and people in the neighborhood help to inject it with life. FREITAG Store Shanghai is a hybrid concept occupying the space between neighborhood and retail. We hope the store, which will open on March 25th, will become a long-lasting place within the community and a hub for the brand’s growth.

https://media.freitag.ch/ja/media/stores/shanghai

Project approach reduces emissions by 144 t CO2 eq (See the link above for details.)

Throughout the entire conversion of the new Shanghai FREITAG Store, the focus was on minimizing CO2 emissions.

Thanks to the use of various measures, they were reduced by around 144 t CO2 eq (approx. 45%).

This figure includes the production, construction and end-of-life stages and corresponds to the amount of CO2 absorbed jointly by 11,500 beech trees in a year.

The same amount of CO2 is also emitted during the production of 205,000 kWh of electricity (East China Power Grid) or the use of 48.2 tonnes of gasoline.

FREITAG 上海店位于上海市中心静安寺区域的北侧。该地区虽然主要为住宅区,但近年来随着小型咖啡馆和商业设施的不断兴起,逐渐呈现出活力与人气。本项目是继苏黎世店之后的大规模门店。

在本次设计中,我们希望将品牌故事与基地及周边环境相结合,提出一个循环型的店铺概念。因此,我们尽可能地利用基地内原有建筑(建于20世纪70~80年代的国营毛巾工厂),并通过结构加固,使其转变为更具长寿命的建筑物。

シ店铺位于连接延平路与胶州路的一条狭窄小巷内(前面道路宽约3米,是高密度住宅区,再建十分困难),同时从两条街道均可望见其姿态。在中国,街道商铺通常2至3年就会更替,而FREITAG与业主签订了长期租约,并提出了严格的设计要求:“Waste is a design error(浪费是设计的错误)”。因此,本项目不仅仅是表面上的可持续设计,而是一个真正着眼于减少CO2排放的“硬核”项目。

施工过程中,原有建筑是由混凝土与砖砌成的封闭空间,开口较少。我们在现场引入小型机械,在部分区域用钢结构进行补强,同时逐步打开建筑立面,使之面向城市敞开,并引入自然采光与自然通风。例如,工地的围挡不再租赁,而是直接采用钢筋压型板,后续在既有立面与新加保温层之间作为饰面继续使用(减少因运输材料带来的环境负担);又如,将拆除的废料与水泥砂浆混合,在现场制成再生砖块,并直接作为一层地面的铺装材料。我们尽可能地在每个环节中避免浪费与资源流失。

在本次改造中,我们重点控制CO2排放量,最终实现了约144吨二氧化碳当量(约45%)的削减。这一数值涵盖了生产、施工和使用后的阶段,相当于11,500棵山毛榉在一年内所吸收的二氧化碳量;换算成能源,相当于华东电网约205,000千瓦时的电力消耗,或48.2吨汽油的燃烧所产生的CO2排放量。

本项目也希望让这家开设在小巷内的店铺成为对社区开放的存在:一层规划了维修工坊;同时沿着贯穿各层的大型中庭设置了垂直储存系统。不同于一般隐藏在后台的设施,这里将其作为店铺空间的中心展示。垂直储存装置在每一层均设有一个,可通过简单的手动机械系统将货物移送至相应楼层。我们希望新店能够成为一个与社区共存、被长久喜爱的场所,并成为承载和传播品牌的“终端”。

READ MORE SHOW LESS